TOMOROBO © Rebar Tying Robot

TOMOROBO © Rebar Tying Robot

TOMOROBO © Rebar Tying Robot

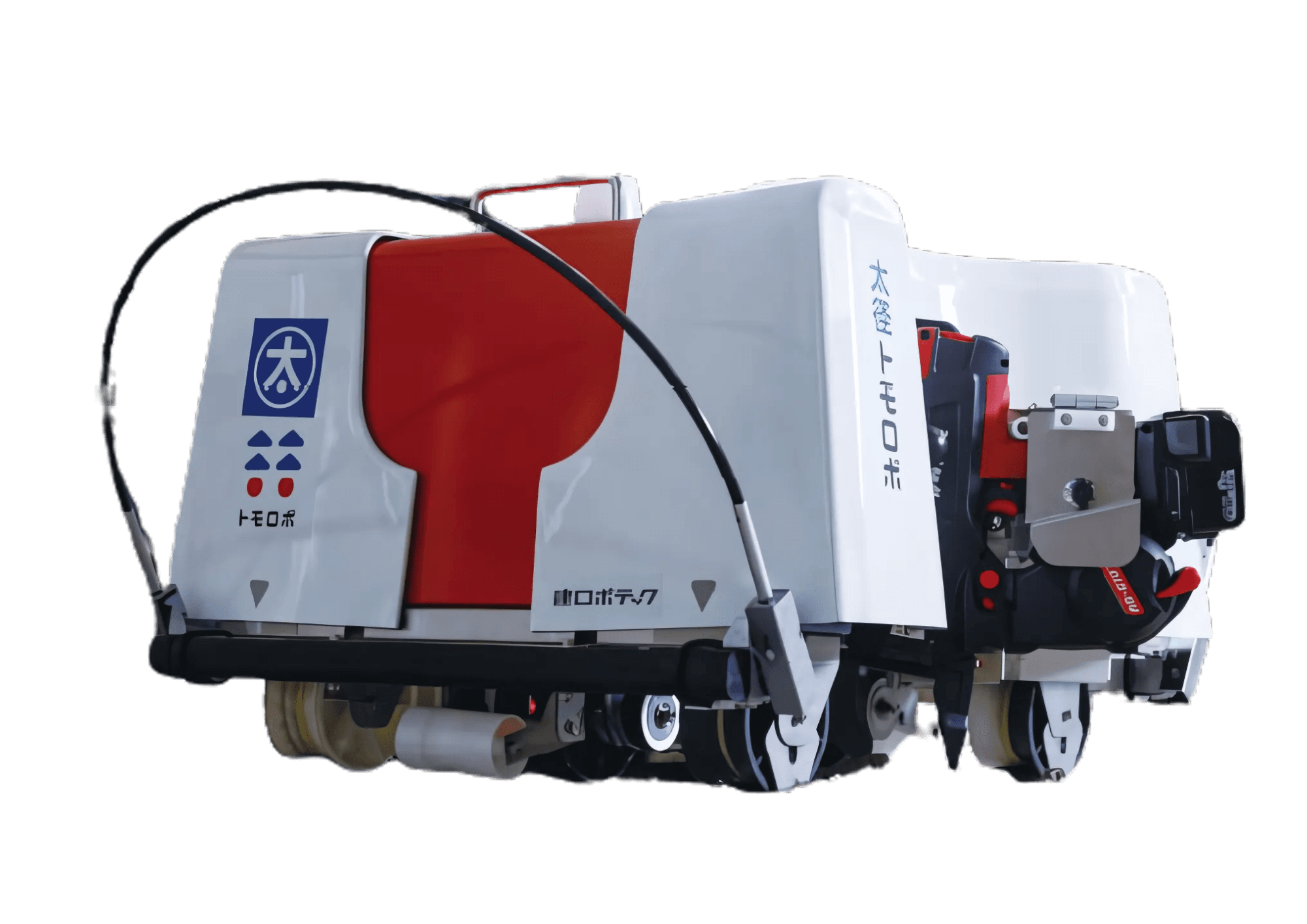

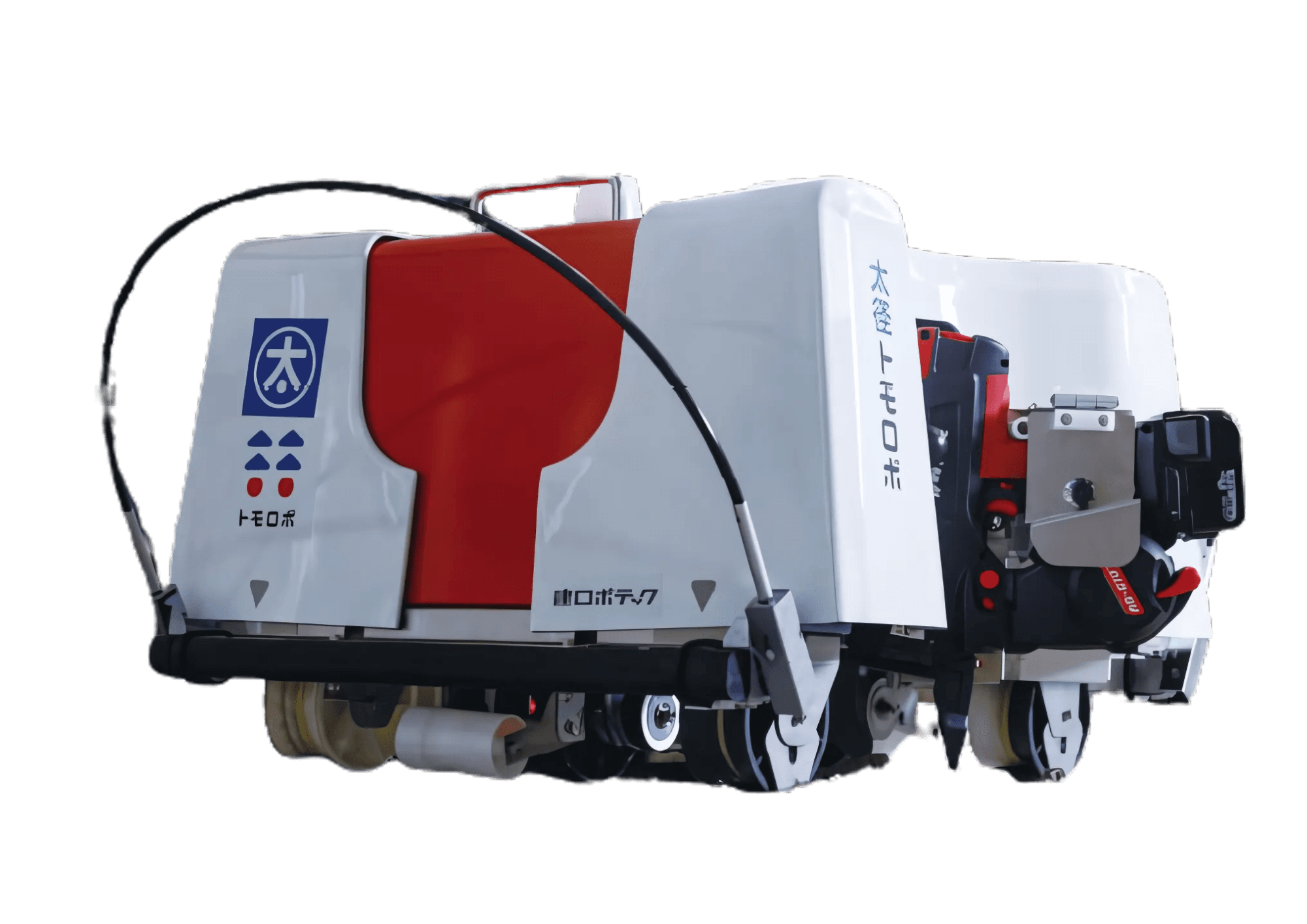

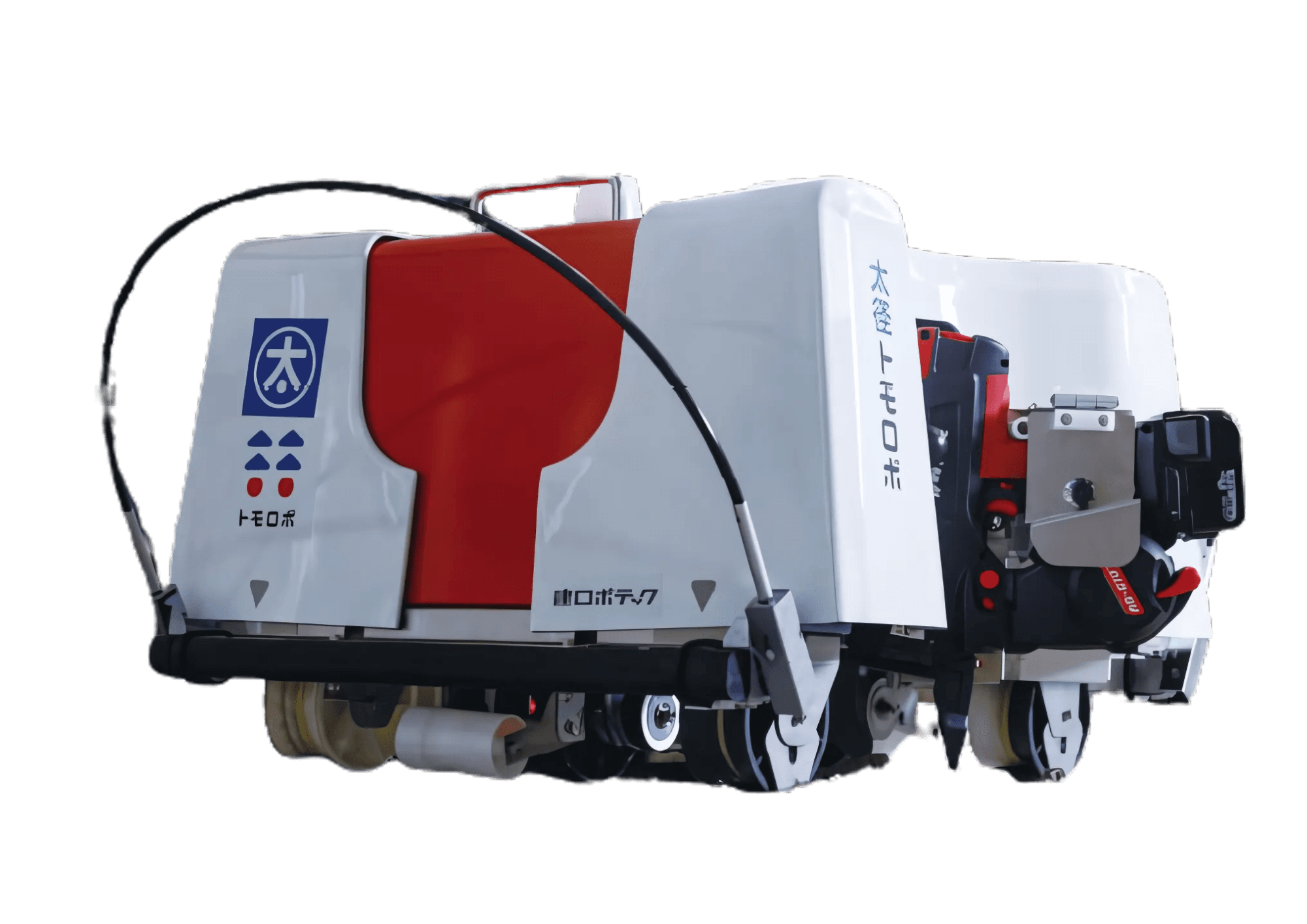

A Collaborative Rebar Tying Robot for Enhanced Site Productivity and Worker Safety

A Collaborative Rebar Tying Robot for Enhanced Site Productivity and Worker Safety

A Collaborative Rebar Tying Robot for Enhanced Site Productivity and Worker Safety

Highlights:

Intelligent Pitch Sensing: Automatically detects intersections and adjusts to 100mm–300mm pitches.

Dual-Tool Efficiency: Achieves tying speeds under 2.7 seconds per location.

12-Hour Battery Life: Lasts a full shift on one 6-hour charge.

Multi-Pattern Tying: Choose from three selectable intersection tying modes.

Safety Sensor System: Dual-position sensors trigger immediate stops for obstacles.

Adjustable Frame: Variable width (63cm–93cm) to suit different site layouts.

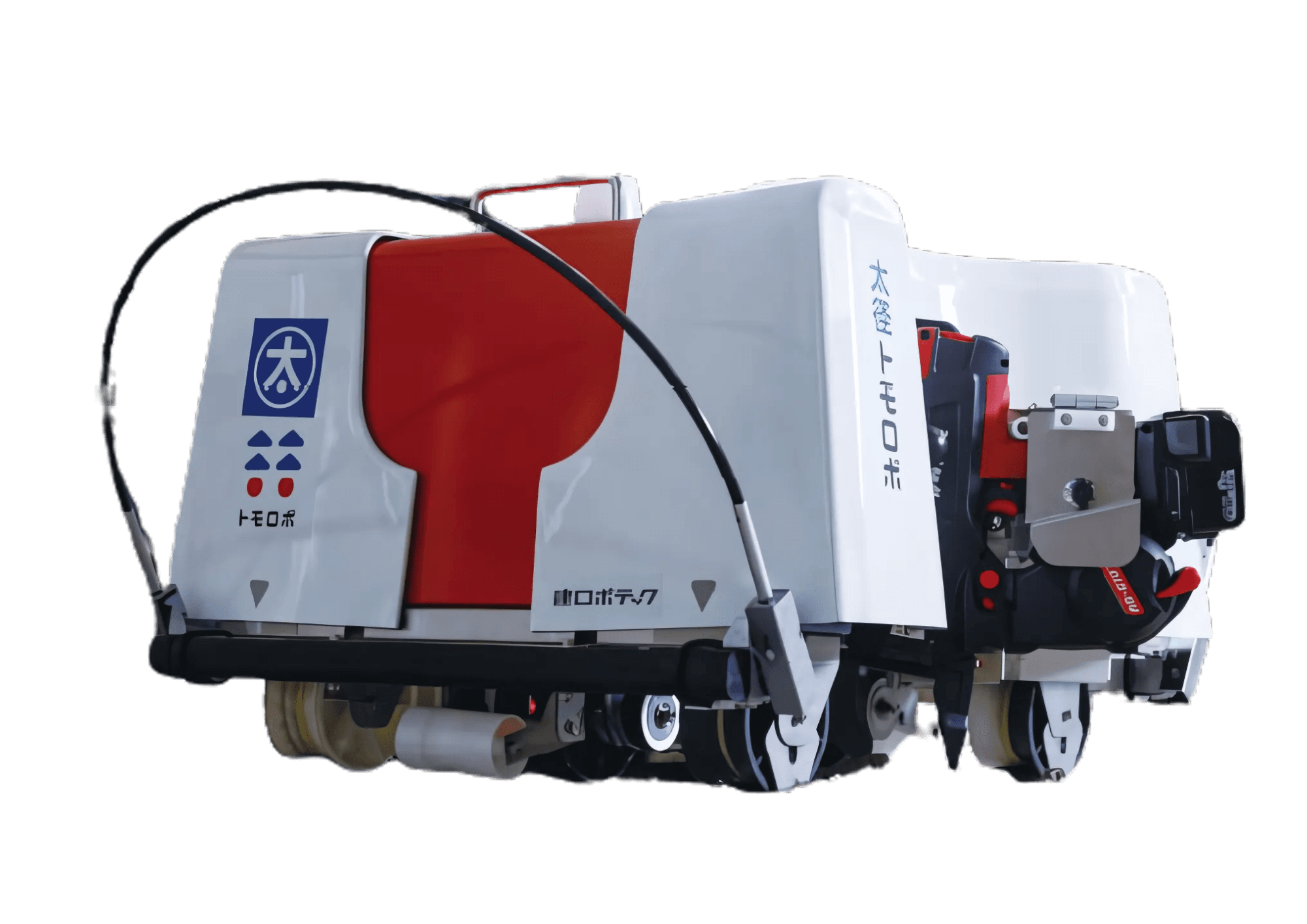

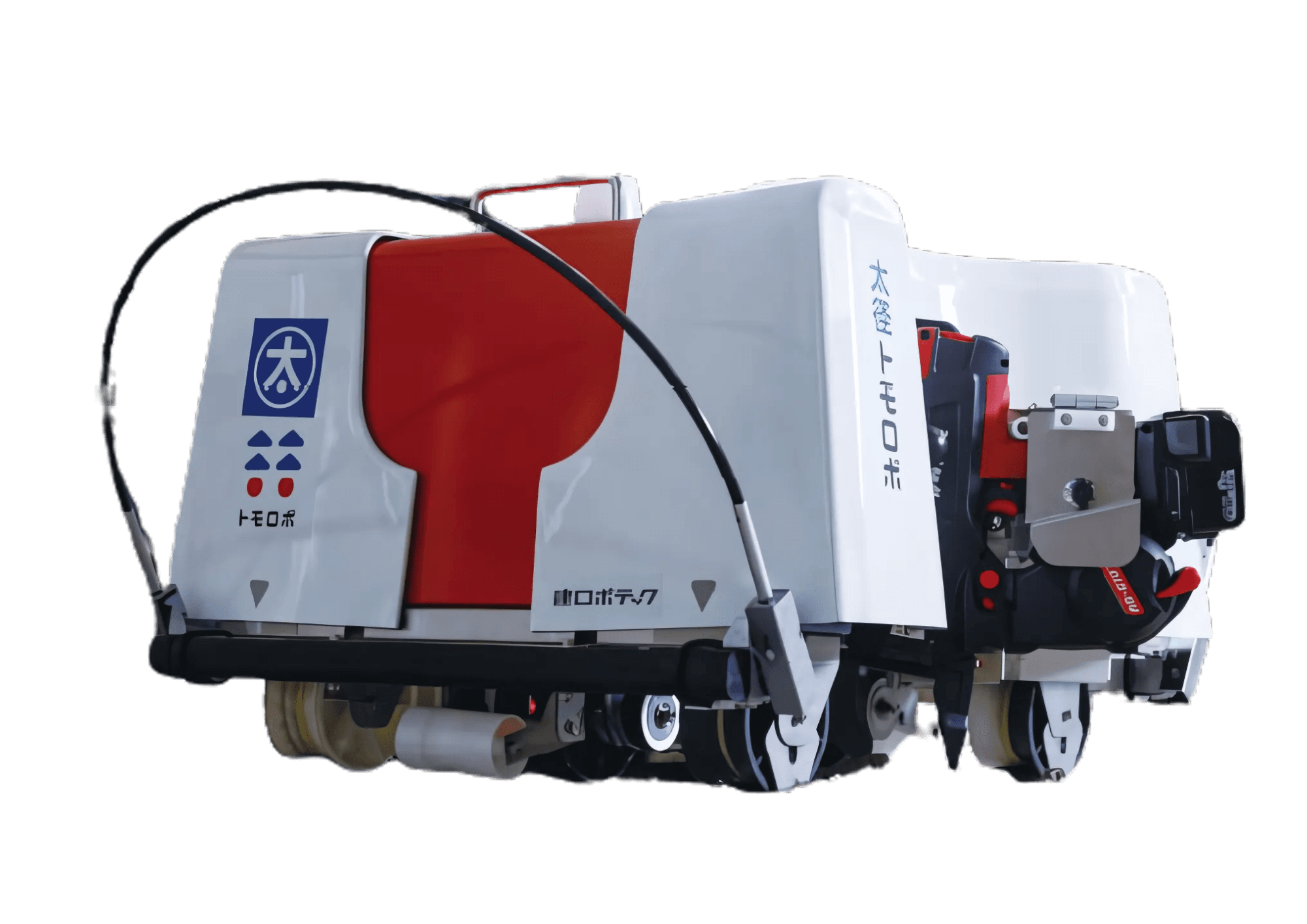

Empowering the Human Workforce through Automation TOMOROBO is a "collaborative robot" (cobot) designed to work alongside people rather than replace them. By automating the tedious and physically demanding task of tying floor slabs, it allows skilled workers to focus on complex areas like vertical walls or hook placements, significantly improving overall worksite productivity.

Versatile Compatibility and Performance This robot is uniquely designed to carry commercially available handheld tools, specifically the MAX RB-441T or RB-611T, via a simple adapter. It is available in two versions: the Standard Model (RTM1-X1-A1) for small diameter rebars (φ10-16mm) and the Large Diameter Model (RTM1-X1-A2) for civil engineering projects (φ16-32mm).

Built for the Rigors of the Construction Site Despite weighing 38.5kg, TOMOROBO is highly portable and can be handled by two people using integrated top handles. It is designed for reliability in harsh conditions, with optional accessories like a dedicated rain cover for light precipitation and the "TOMOROBO Slider" to help a single operator manage multiple units simultaneously.

Stunning Features:

Collaborative Design: Functions safely in shared workspaces with human crews.

Rapid Deployment: Uses standard, off-the-shelf tying tools for easy setup.

Precision Sensing: Adapts to uneven rebar heights and angles with ±20mm pitch allowance.

Extended Autonomy: Continuous 12-hour operation ensures maximum daily output.

Enhanced Safety: Dual-level contact sensors and rebar end detection prevent site accidents.

Optimized for Infrastructure: Available models for both general construction and large-scale civil engineering.

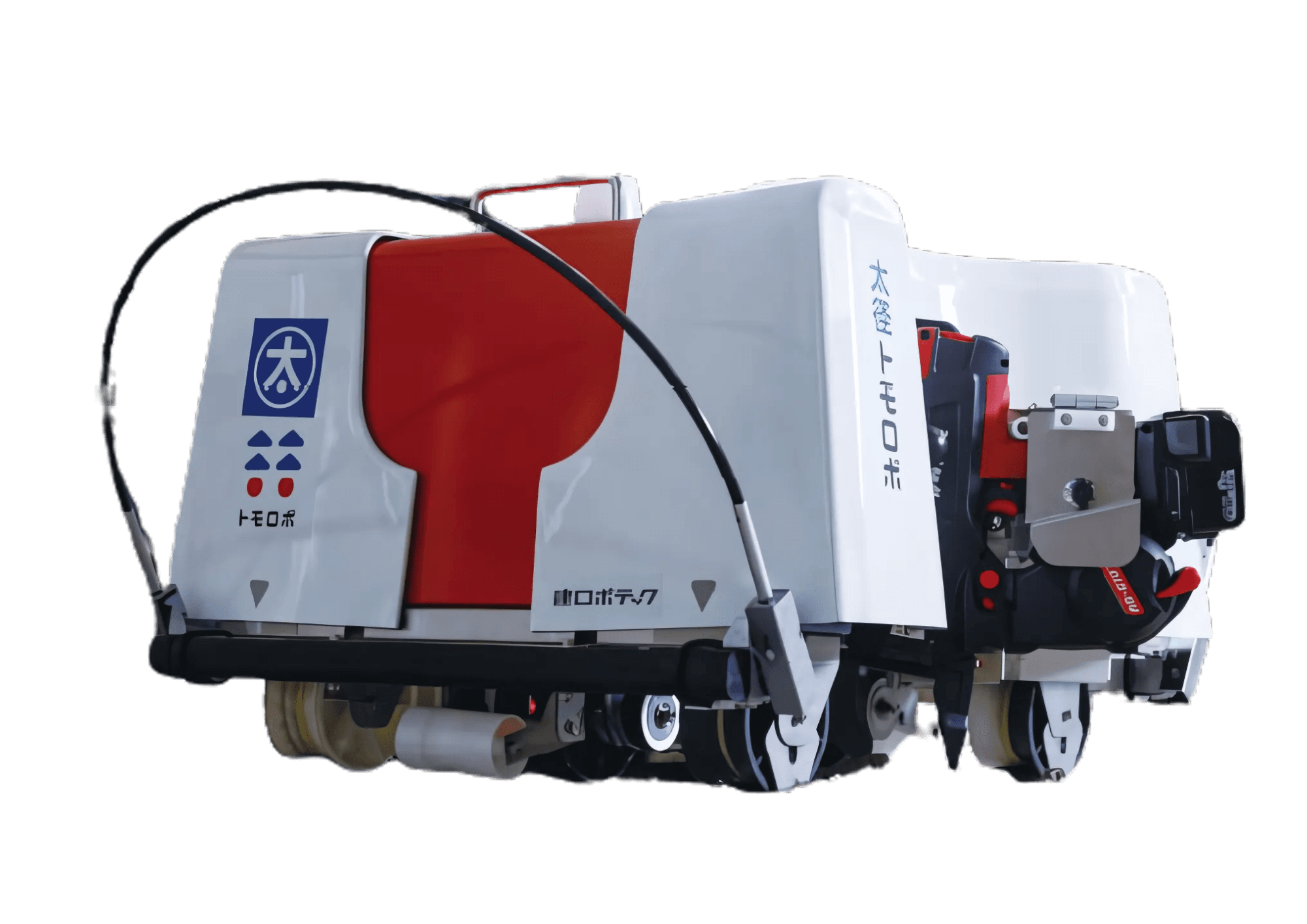

Empowering the Human Workforce through Automation TOMOROBO is a "collaborative robot" (cobot) designed to work alongside people rather than replace them. By automating the tedious and physically demanding task of tying floor slabs, it allows skilled workers to focus on complex areas like vertical walls or hook placements, significantly improving overall worksite productivity.

Versatile Compatibility and Performance This robot is uniquely designed to carry commercially available handheld tools, specifically the MAX RB-441T or RB-611T, via a simple adapter. It is available in two versions: the Standard Model (RTM1-X1-A1) for small diameter rebars (φ10-16mm) and the Large Diameter Model (RTM1-X1-A2) for civil engineering projects (φ16-32mm).

Built for the Rigors of the Construction Site Despite weighing 38.5kg, TOMOROBO is highly portable and can be handled by two people using integrated top handles. It is designed for reliability in harsh conditions, with optional accessories like a dedicated rain cover for light precipitation and the "TOMOROBO Slider" to help a single operator manage multiple units simultaneously.

Stunning Features:

Collaborative Design: Functions safely in shared workspaces with human crews.

Rapid Deployment: Uses standard, off-the-shelf tying tools for easy setup.

Precision Sensing: Adapts to uneven rebar heights and angles with ±20mm pitch allowance.

Extended Autonomy: Continuous 12-hour operation ensures maximum daily output.

Enhanced Safety: Dual-level contact sensors and rebar end detection prevent site accidents.

Optimized for Infrastructure: Available models for both general construction and large-scale civil engineering.

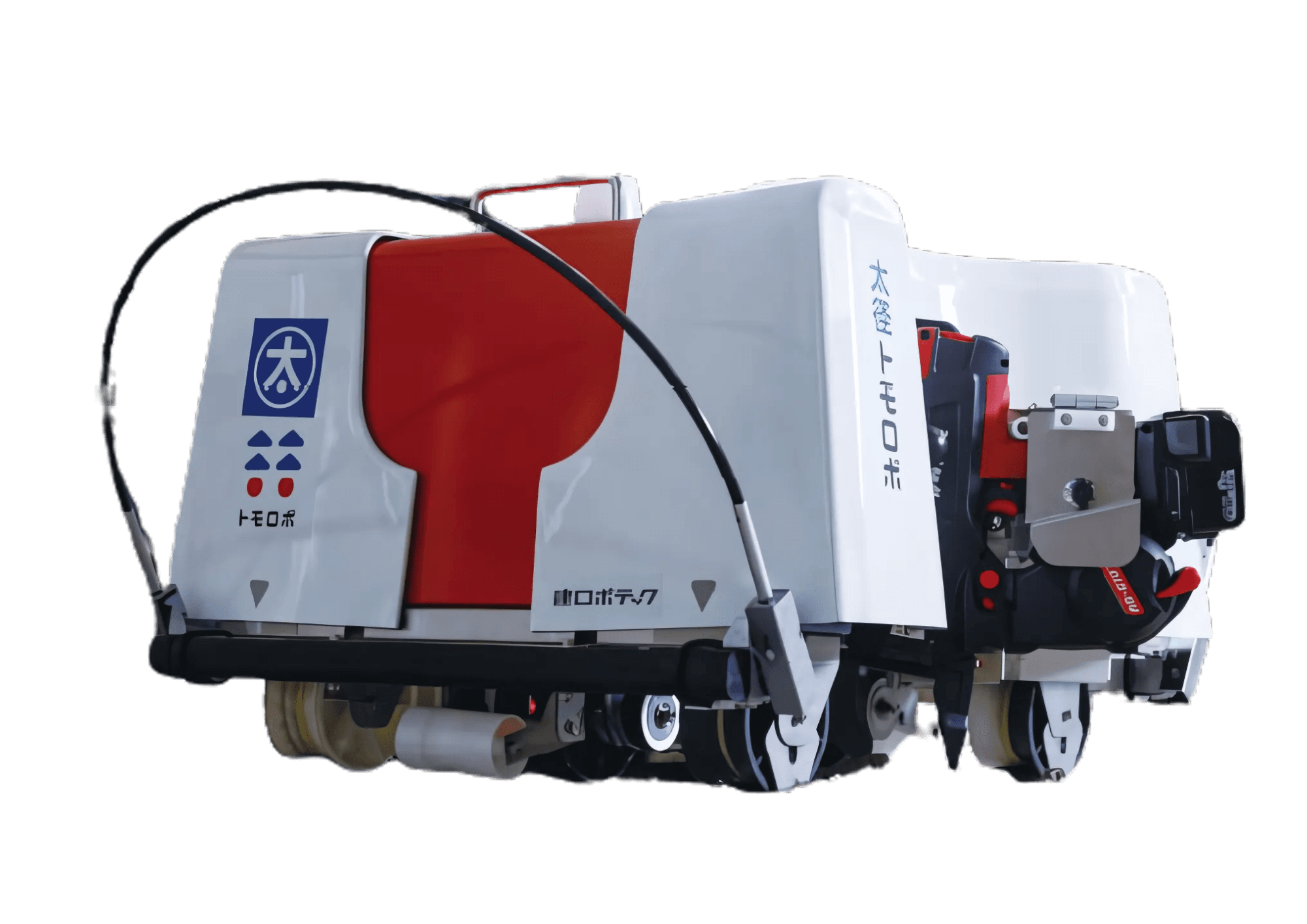

Empowering the Human Workforce through Automation TOMOROBO is a "collaborative robot" (cobot) designed to work alongside people rather than replace them. By automating the tedious and physically demanding task of tying floor slabs, it allows skilled workers to focus on complex areas like vertical walls or hook placements, significantly improving overall worksite productivity.

Versatile Compatibility and Performance This robot is uniquely designed to carry commercially available handheld tools, specifically the MAX RB-441T or RB-611T, via a simple adapter. It is available in two versions: the Standard Model (RTM1-X1-A1) for small diameter rebars (φ10-16mm) and the Large Diameter Model (RTM1-X1-A2) for civil engineering projects (φ16-32mm).

Built for the Rigors of the Construction Site Despite weighing 38.5kg, TOMOROBO is highly portable and can be handled by two people using integrated top handles. It is designed for reliability in harsh conditions, with optional accessories like a dedicated rain cover for light precipitation and the "TOMOROBO Slider" to help a single operator manage multiple units simultaneously.

Stunning Features:

Collaborative Design: Functions safely in shared workspaces with human crews.

Rapid Deployment: Uses standard, off-the-shelf tying tools for easy setup.

Precision Sensing: Adapts to uneven rebar heights and angles with ±20mm pitch allowance.

Extended Autonomy: Continuous 12-hour operation ensures maximum daily output.

Enhanced Safety: Dual-level contact sensors and rebar end detection prevent site accidents.

Optimized for Infrastructure: Available models for both general construction and large-scale civil engineering.

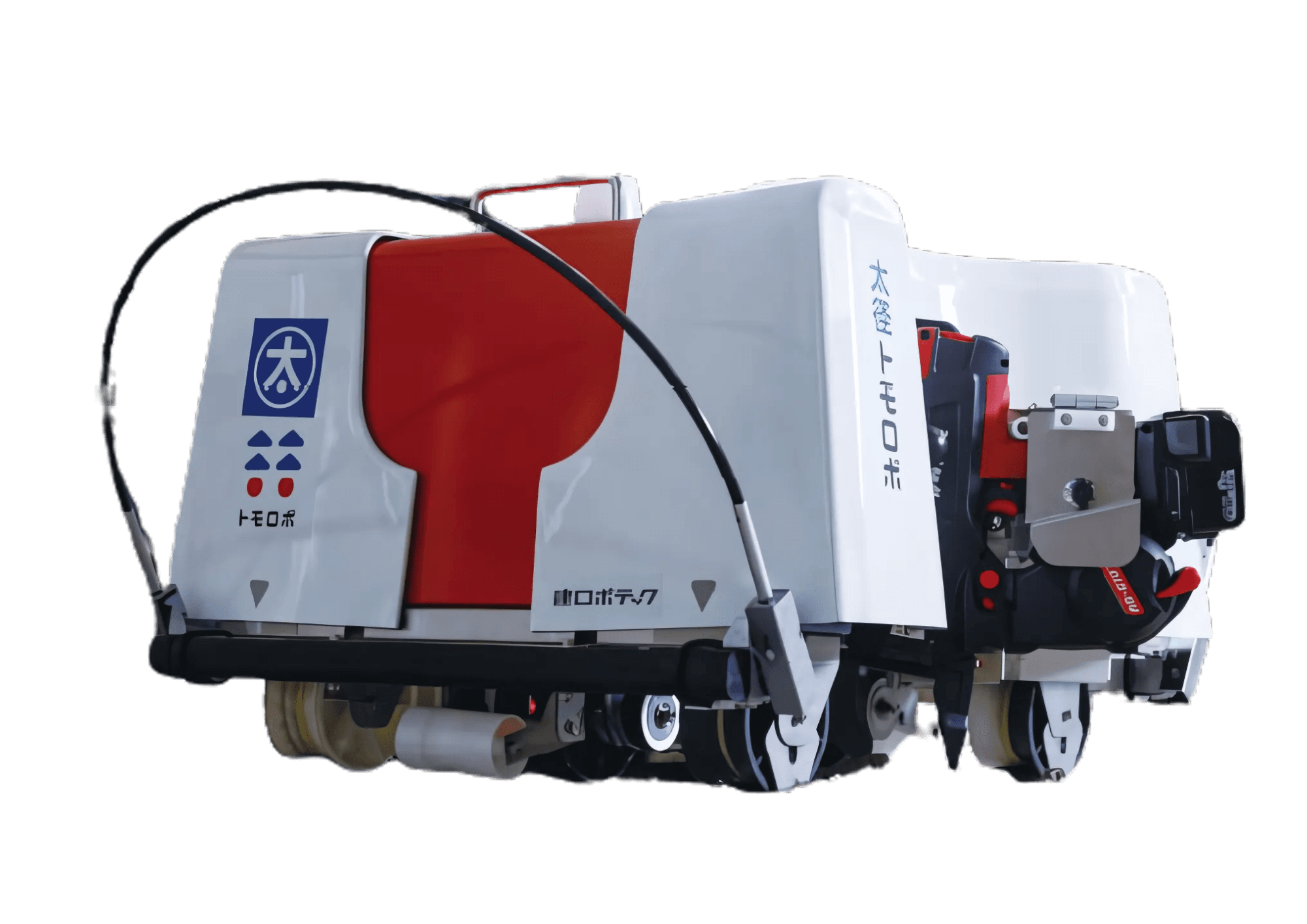

Empowering the Human Workforce through Automation TOMOROBO is a "collaborative robot" (cobot) designed to work alongside people rather than replace them. By automating the tedious and physically demanding task of tying floor slabs, it allows skilled workers to focus on complex areas like vertical walls or hook placements, significantly improving overall worksite productivity.

Versatile Compatibility and Performance This robot is uniquely designed to carry commercially available handheld tools, specifically the MAX RB-441T or RB-611T, via a simple adapter. It is available in two versions: the Standard Model (RTM1-X1-A1) for small diameter rebars (φ10-16mm) and the Large Diameter Model (RTM1-X1-A2) for civil engineering projects (φ16-32mm).

Built for the Rigors of the Construction Site Despite weighing 38.5kg, TOMOROBO is highly portable and can be handled by two people using integrated top handles. It is designed for reliability in harsh conditions, with optional accessories like a dedicated rain cover for light precipitation and the "TOMOROBO Slider" to help a single operator manage multiple units simultaneously.

Stunning Features:

Collaborative Design: Functions safely in shared workspaces with human crews.

Rapid Deployment: Uses standard, off-the-shelf tying tools for easy setup.

Precision Sensing: Adapts to uneven rebar heights and angles with ±20mm pitch allowance.

Extended Autonomy: Continuous 12-hour operation ensures maximum daily output.

Enhanced Safety: Dual-level contact sensors and rebar end detection prevent site accidents.

Optimized for Infrastructure: Available models for both general construction and large-scale civil engineering.

TOMOROBO © Rebar Tying Robot

TOMOROBO © Rebar Tying Robot

TOMOROBO © Rebar Tying Robot

TOMOROBO © Rebar Tying Robot

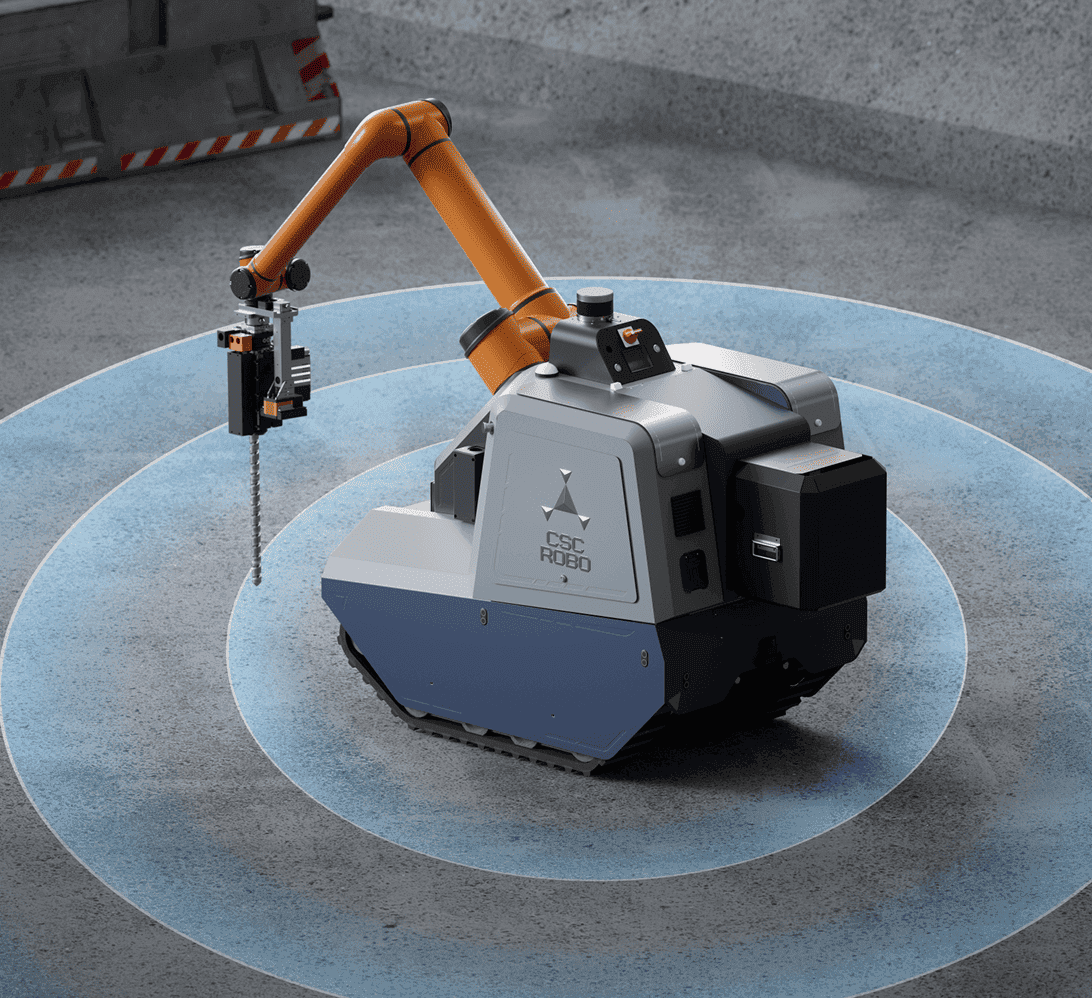

More Products You'll Like

More Products You'll Like

More Products You'll Like

More Products You'll Like

Check Out More Related Products that you'll Love

Check Out More Related Products that you'll Love

Check Out More Related Products that you'll Love

Check Out More Related Products that you'll Love

ModernX AI

ModernX AI

Copyright © 2023 FramerIt | Made with ❤️ by Samar Jamil

Copyright © 2023 FramerIt | Made with ❤️ by Samar Jamil